|

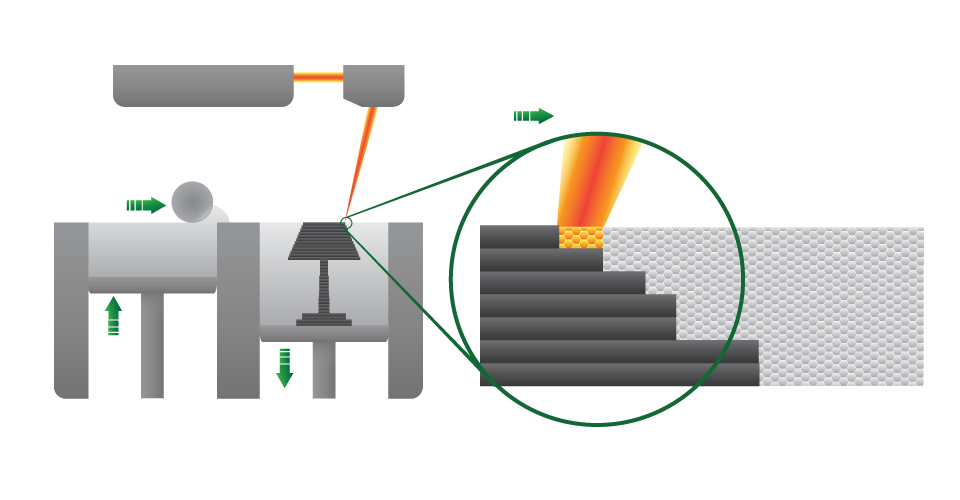

Selective Laser Sintering

Compared to other rapid manufacturing methods, SLS can produce parts from a relatively wide range of commercially available powder materials, including:

The physical process can be full melting, partial melting, or liquid-phase sintering, and depending on the material, up to 100% density can be achieved with material properties comparable to those from conventional manufacturing methods. In many cases large numbers of parts can be packed within the powder bed, allowing very high productivity.

|

|

Specializing in 3D Engineering Solutions, 3D Printing Services (Polyjet , Polyjet Matrix Technology) Fused Deposition Modeling (FDM), Sterolithography (SLA), and Selective Laser Sintering (SLS), our team of certified engineer designers offer engineering design solutions which enables Rapid Prototyping Services Canada to always be strategic and innovative to better your Product Development experience. With the leading edge technology for all 3D Printing, Product design, Product development and rapid prototyping applications, we are competitively priced and always deliver quality results to our clients. With 3D modeling, rapid prototyping, and the latest additive manufacturing technologies, Rapid Prototyping Services Canada believes in delivering value to our clients through meeting budget requirements, timelines, and providing expert consultation. Our customers range from all over the USA and Canada. We also service the following areas : British Columbia, Toronto Ontario, Vaughan Ontario, Markham Ontario, Thornhill Ontario, Richmond Hill Ontario, Concord Ontario, Mississauga, Durham Region, Oshawa, Etobicoke, Cambridge, Brampton, Whitby, Peel, Woodbridge, Barrie, York region, Maple, Aurora, Newmarket, Cambridge, Whitby, Peel, Woodbridge, Barrie, York, Maple, Aurora, Newmarket Ontario and surrounding areas. Nationally we service Vancouver , Calgary , Edmonton, Alberta, Montreal Quebec, Ottawa and Fort McMurray. In the United States we provide rapid prototyping services to New York, Los Angeles, Chicago, Houston, Philadelphia, Phoenix, San Antonio, San Diego, Dallas, San Jose, Indianapolis, San Francisco, Austin, Columbus, Fort Worth, Charlotte, Detroit, Memphis, Baltimore, Boston, Seattle, Washington, Nashville, Denver, Las Vegas, Sacramento, Silicon Valley, Raleigh, Pittsburgh, Portland, Atlanta, Springfield, Scottsdale, Miami, Cleveland, Oakland, Minneapolis, Mexico City, and Washington DC. |